Characteristic

– Class 5 according to PN-EN 303-5:2012

– Ecodesign

– High efficiency

– Automatic work

– Fast and easy operation

– Economical fuel combustion

– Smokeless and ecological combustion

– Ability to control the boiler’s operation via Internet (option)

– Possibility to install the fuel tank on the left or right side of flues

PRADO

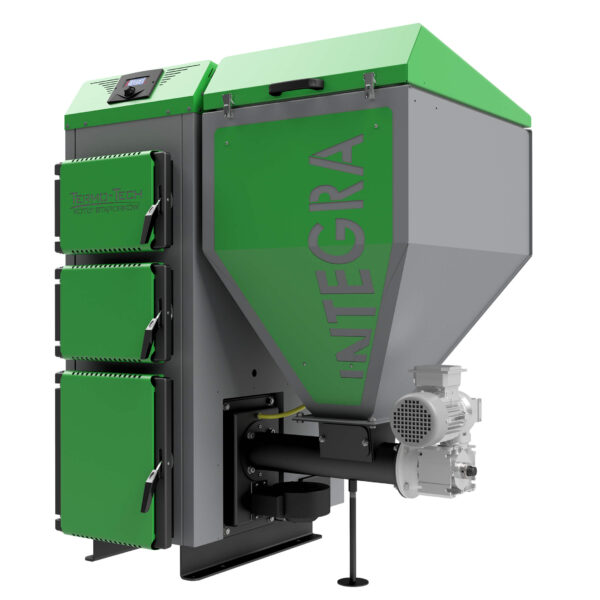

The Prado model boilers with cast iron retort burner are intended for water open system central heating installations with both gravitational and forced water circulation under the condition of installing a cooling coil and open system with both gravitational and forced water circulation. The installation must be secured according to currently valid and detailed national provisions. Steel Prado model boilers with automatic fuel supply system are intended for work in central heating installations and domestic hot water preparation installations in housing development buildings, i.e. single family houses, commercial pavilions, garages, and utility buildings. Boilers constitute a steel structure welded from certified 6 mm thick boiler sheets that ensure a long-term use. The controller handles CH and DHW pumps, as well as auxiliary pump and valve actuator. There is a possibility to connect room regulator and SafeIT (control via Internet) module.

| L.p | Specification | J.m | Information | ||||

| 1. | Boiler type | Prado 18 | Prado 22 | Prado 25 | Prado 28 | ||

| 2. | Nominal thermal power | kW | 18 | 22 | 25 | 28 | |

| 3. | Range of power for coal | kW | 5,4-18 | 6,6-22 | 7,5-25 | 8,1-28 | |

| 4. | Heating surface of the boiler | m² | 1,8 | 2,2 | 2,5 | 2,9 | |

| 5. | Water capacity of the boiler | l | 62 | 77 | 83 | 88 | |

| 6. | Size of heated surface | m² | up to 180 | up to 220 | up to 250 | up to 280 | |

| 7. | Boiler class due to PN-EN 303-5 | 5 | |||||

| 8. | Efficiency | % | 89,6 | 90,7 | 90,67 | 90,1 | |

| 9. | Capacity of the storage chamber | dm³ | 216 | 232 | 260 | 282 | |

| 10, | Combustion upon nominal power | h | 51/180 | 55/195 | 68/189 | 43/152 | |

| 11. | Required capacity of the heat accumulator Qmin>0,3QN | l | 360 | 440 | 500 | 560 | |

| 12. | Exhaust mass flow | g/s | 14,6/4,4 | 14,5/6 | 16,1/6,5 | 18,2/7,8 | |

| 13. | Exhaust fumes temperature | Nominal power | ºC | 173,2/183,6 | |||

| Minimum power | ºC | 94,1-110 | |||||

| 14. | Maximum working temperature (water supply) | ºC | 80 | ||||

| 15. | Minimum working temperature cold water | ºC | 10 | ||||

| 16. | Minimum working temperature (return) | ºC | 55 | ||||

| 17. | Power consumption | Nominal power | W | 250 | |||

| Minimum power | W | 250 | |||||

| 18. | Maximum permissible working pressure | MPa | 0,25 | ||||

| 19. | Test pressure | MPa | 0,5 | ||||

| 20. | Required exhaust flow | mbar | 0,18 | 0,22 | 0,24 | 0,25 | |

| 21. | Flow resistance (10K) | mbar | 2,2-4,0 | ||||

| 22. | Fuel | Black coal sort of pea, granulation 5-25mm | |||||

| 23. | Minimum chimney height | m | 6 | 7 | 7 | 8 | |

| 24. | Diameter of the flue | mm | Ø158 | ||||

| 25. | Diameter of the drain pipe | G | 1/2″ | ||||

| 26. | Power supply | v/Hz/A | 230 / 50 / 0,5÷3,15 | ||||

| 27. | Power consumption in standby mode | W | 11 | ||||

| 28. | Emission of noise | dB | 45,5 | ||||

| 29. | Cross-section of the chimney hole – minimum | cm² | 158 | 25 | 244 | 274 | |

| 30. | Mass of the boiler (±5%) | kg | 385 | 425 | 444 | 486 | |

| 31. | Diameter of supply and return pipe | G | 1 1/2″ | ||||

| 32. | Dimension | A | mm | 798 | 862 | ||

| B | mm | 1063 | 1127 | ||||

| C | mm | 415 | 295 | ||||

| D | mm | 1147 | 1247 | 1317 | 1317 | ||

| E | mm | 857 | 957 | 1027 | 1027 | ||

| F | mm | 158 | |||||

| G | mm | 1116 | |||||

| H | mm | 1345 | 1445 | 1515 | 1515 | ||

| I | mm | 260 | |||||

| J | mm | 103 | |||||

| K | mm | 465 | |||||